Project Gallery

Explore images from our Coal Handling Plant monitoring and control system project

Image 1 of 3

Objective

This project develops a comprehensive robotic and sensor-based control system for coal handling plants. It integrates real-time monitoring, anomaly detection, and PLC automation to optimize conveyor system operations, improve safety, and reduce maintenance costs.

Technical Overview

Sensors

Distance sensors are used for conveyor belt data collection, enabling real-time monitoring of belt position, alignment, and operational parameters.

Control System

LVDTs (Linear Variable Differential Transformers) are finalized for sway input. PLC logic is optimized for real-time master idler control, ensuring precise alignment and operation.

Automation

Sway switches are analyzed for fault detection and master idler alignment, providing automated monitoring and corrective actions.

Innovation

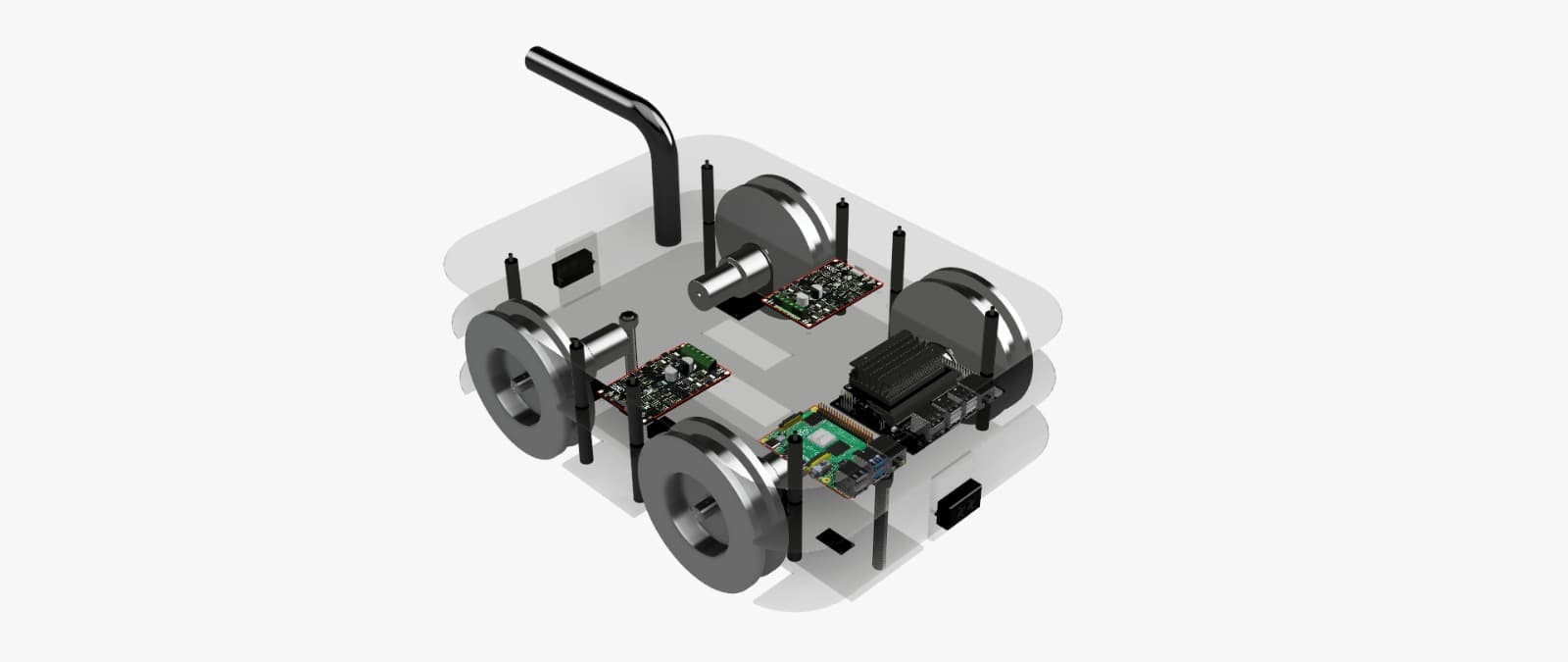

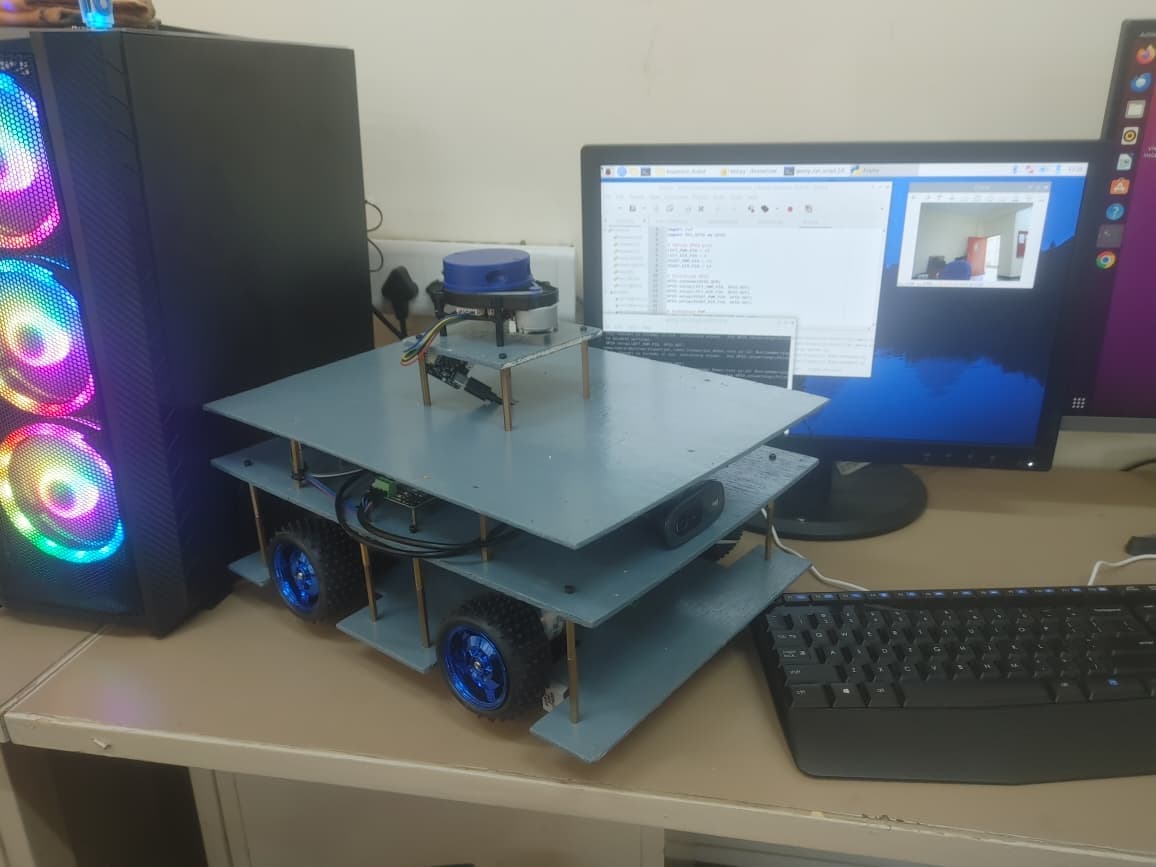

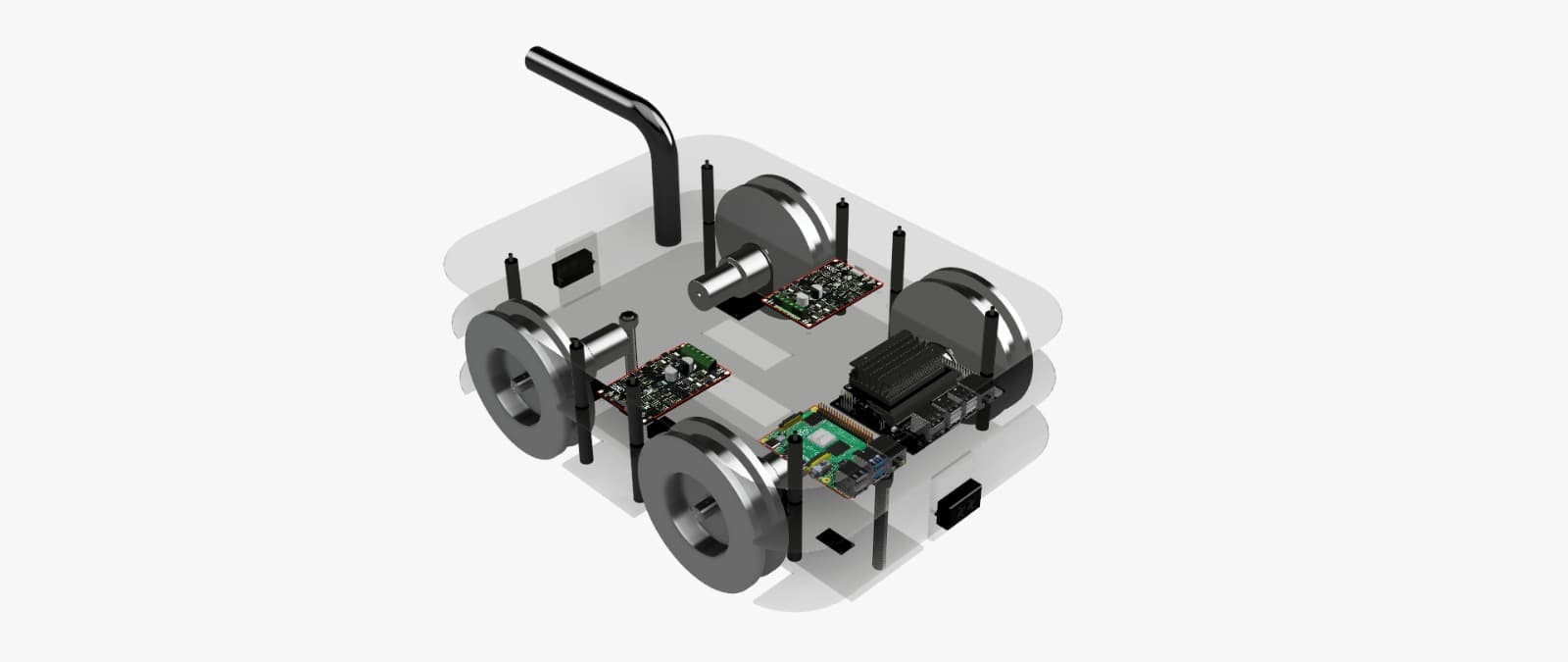

A Tracked Robot is introduced for conveyor belt inspection and monitoring, enabling autonomous inspection capabilities.

Tracked Robot Features

Tracked Wheel System

Designed for rough terrain stability, enabling reliable operation in challenging industrial environments.

High-Resolution Camera

Provides visual inspection capabilities for detailed monitoring and documentation of conveyor belt conditions.

Advanced Sensors

Equipped with sensors for detecting heat, vibration, and obstructions, enabling comprehensive monitoring.

Wireless Communication

Features wireless communication and power management for extended operational autonomy.

Control & Feedback

Remote Operation

The system supports remote operation via console or tablet, providing flexible control and monitoring capabilities from any location.

Live Monitoring

Provides live video feed and anomaly alerts with historical data logging, enabling comprehensive monitoring and analysis of system performance.